Painting & Process Systems

Solutions for Industrial Painting

Grivan Group offers comprehensive solutions for industrial painting plants, supporting clients through every phase of the project: from initial consulting to implementation, and through to post-installation maintenance.

Core Business and Target

We specialize in both revamping existing plants and designing and building systems for greenfield and brownfield projects, delivering efficient, scalable, and technologically advanced solutions.

We primarily operate in the automotive sector but also support general industrial finishing, including painting and treatment of plastic components (both interior and exterior), alloy or steel wheels, and metal parts and structures.

Our Solutions

We design and install complete turnkey plants, featuring technologies and processes such as:

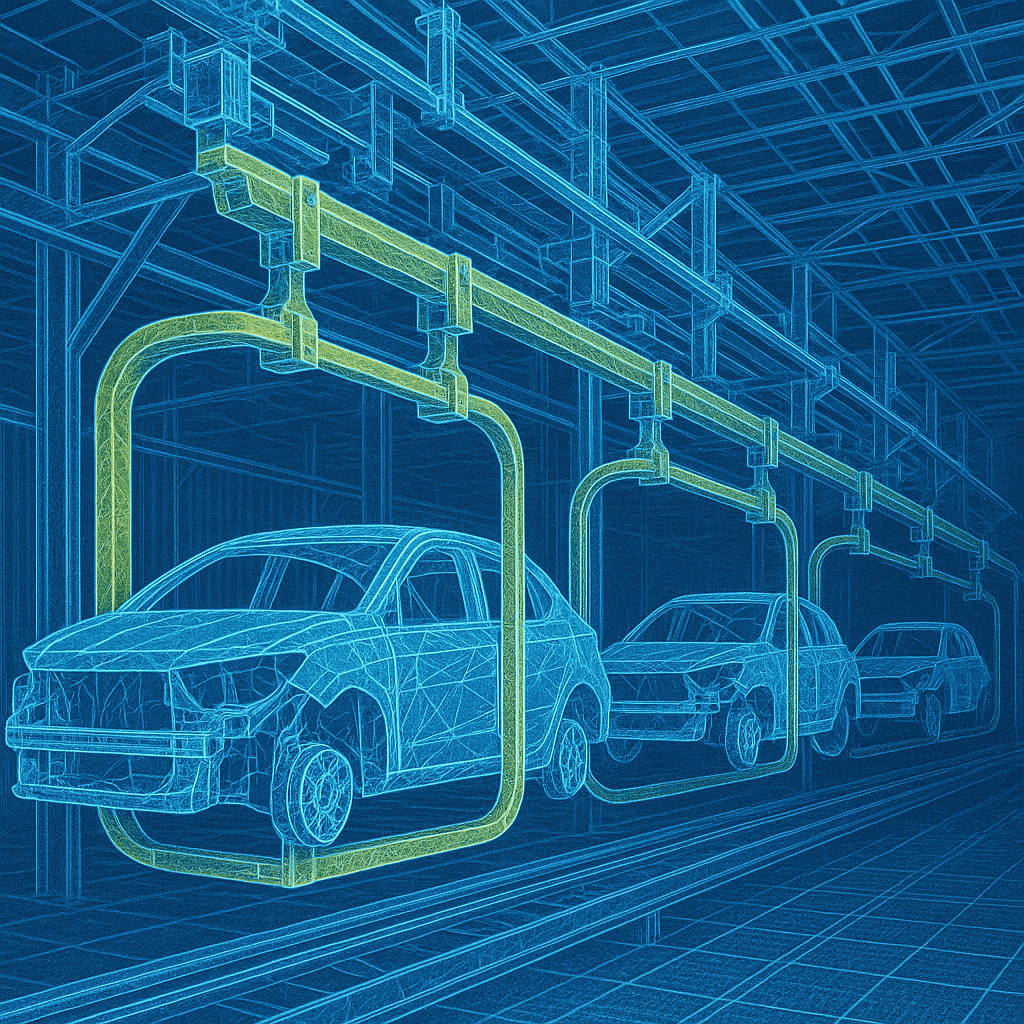

Body Surface Treatment Systems

Paint Booths

Paint Application Systems

Paint Supply Systems

Curing Ovens

Working Decks

Combined Paint and Curing Booths

Environmental Technology

Applications

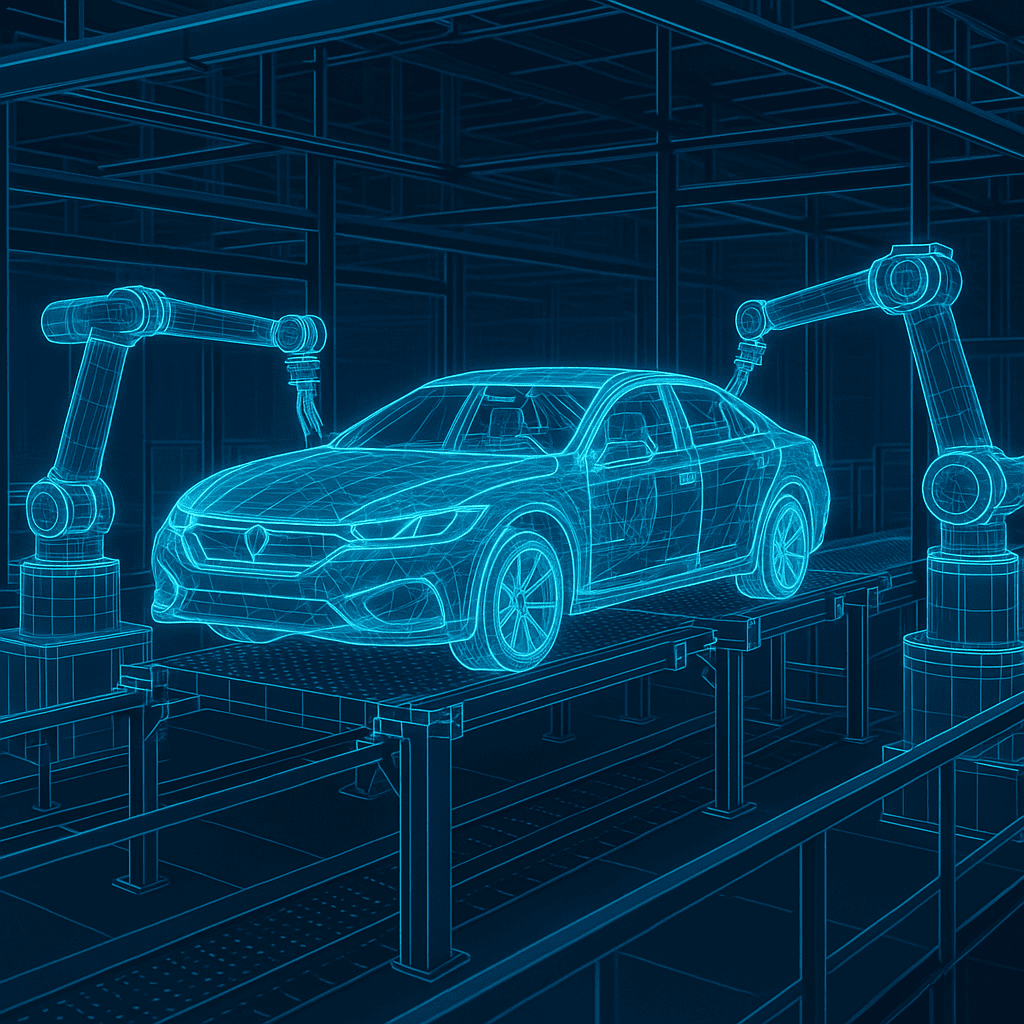

We are able to integrate painting robots from leading brands (ABB, Fanuc, KUKA, Yaskawa), along with advanced technologies for:

-

Airless, pneumatic, and high-speed painting

-

Automated blowing and cleaning applications

-

Bonding and sealing with various types of flows

-

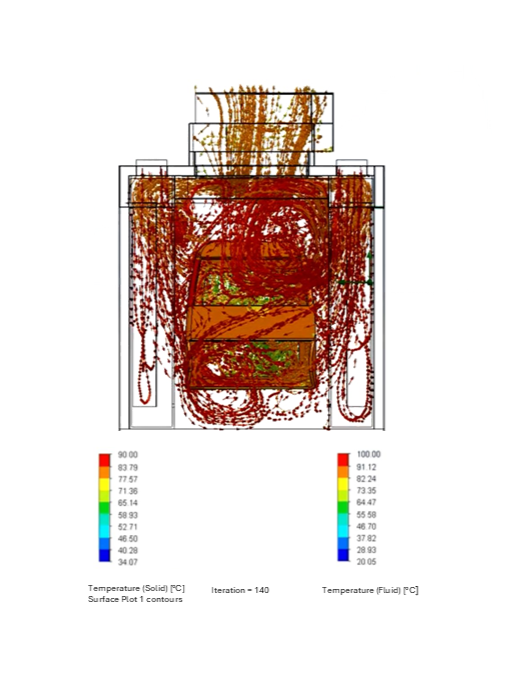

Machine vision and 3D detection with real-time correction

-

Tool tracking and automatic calibration

We also offer offline process simulation systems, essential for optimizing production times and cycles before commissioning.

Additional Services

Grivan Group also offers its clients the following services:

-

Engineering and consulting for painting plants

-

Supply of steel structures and mechanical components

-

Project management

-

Design engineering

-

Installation

-

Commissioning

-

On-site supervision

-

Training

-

Quality audits and system inspections

-

Plant maintenance and support services

-

Spare parts service

-

Process modifications and optimization